Experimental And Computational Study Of A. Modeling Evaporating Liquid Spray Step 1.

Ansys Cfx Spary Modelling Computational Fluid Dynamics Is The Future

Modeling ANSYS Fluent Tutorial Steady Vehicle Aerodynamic Simulation for Begginers Spray Modeling Tutorial Using Ansys Spray Modelling using ANSYS-CFX Spray modelling this is a test trial of water spraying using a novel spray design.

. The nozzle diameter is 075mm and the injection velocity is 150 ms. If you have tutorial or other material about the spray penetration length calaulation in ansys fluent kindely send me. In Fluent the user can use a special configuration to model primary breakup by VOF and then as droplets form track them more efficiently using DPM.

Application of the VOF-DPM hybrid model on industry relevant jet in crossflow and diesel sprays shows encouraging results. The present tutorial used. Modeling Evaporating Liquid Spray.

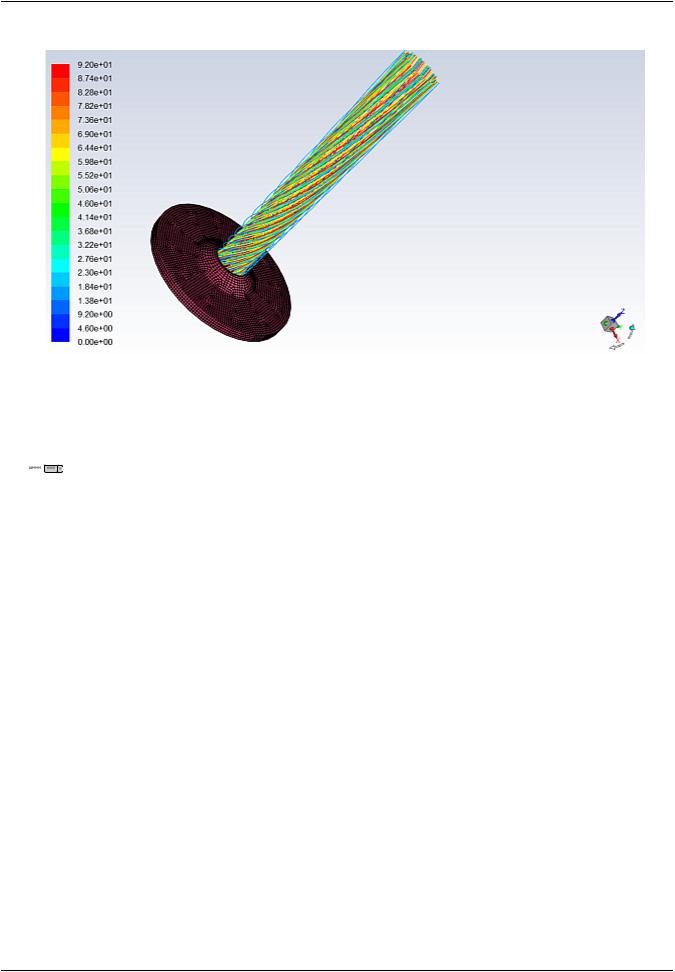

Read in the mesh file sectormsh. A computational fluid dynamics CFD modeling of the spray formation process in a Diesel engine is developed in ANSYS-FLUENT using its discrete phase modeling DPM capability and its IC-engine module. The drying chamber consists of two cylindrical and conical.

Tutorial 17 modeling evaporating liquid spray. Six-vane swirler and bluff-body geometry. 1- You have to see what parameters from the paper where of interest and at what locations.

Ive already done my first setup but the result isn. In this model two primary models are well established The Volume of Fluid VOF model tracks the liquid-gas interface. The required geometry for the spray tutorial is provided by sending me an email.

Select dynamic-drag from the Drag Law drop-down list in the Drag Page 421. We take the effect of the earths gravity into account for the spray dryer modeling so that its value is 981 ms-2. I have tried all the tutuorials related to what I would like to achieve but I have been unable to succesfulling achieve the solution I want.

General Settings ANSYS FLUENT 120 Tutorial Guide - Modeling Evaporating. Both fluids need to be set as continuous fluid so it should not be a large breakup model simulation to investigate every single drop. ANSYS FLUENT For Spray Combustion VOF DPM spray model.

File Read Mesh. Change the periodic type of periodic-a to rotational. Combustion Modeling DPM Spray Modeling.

A Select Rotational in the Periodic Type list. Spray Modeling Tutorial Using Ansys Cfx 301 Moved Permanently. The task is to simulate a water spray which is going to be injected into air as ideal gas.

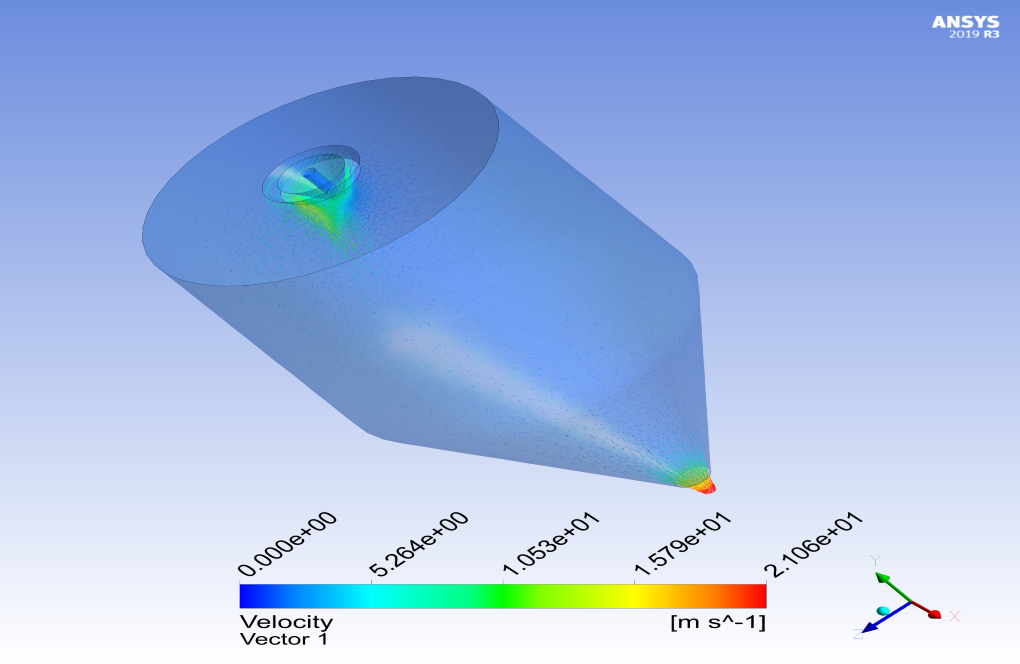

We assume the incompressible flow so the solution is pressure-based. These simulations can then be used to compare a stable n-heptane flame H1S1 and an n-heptane flame that is close to blowout H1S2. The simulation shows that the spray pattern is a 60-degree.

B Click OK to close the Periodic dialog box. Cfd analysis of convergent divergent supersonic nozzle. Boundary Conditions periodic-a Edit.

A new VOF-DPM transition model in ANSYS Fluent VOF-DPM transition tool combined with dynamic mesh adaption enables to carry out a detailed numerical analysis of spray behavior at affordable computational cost. The Design Modeler software design the 3-D geometry of the Spray Dryer. Spray Primary Breakup Modeling The primary breakup of an spray is modeled through the LISA method that is described by Senecal et al.

But when the run starts it is not able to retain any of the spray particles. Aerodynamics combustions hydrodynamics mixtures of liquidssolidsgas particles dispersions Customizable numerical models. Here is the latest tutorial for spray modelling just click on the image on the right hand side to down load it.

Geometry of Spray Dryer. Computational study of effects of drop size distribution. Fuel flow analysis of injector nozzle ijesit.

What Is The Best Model To Model A Air Water Mist Jet In. ANSYS Fluent Model Of Water Mist Spray In Air Stream. I am looking to model a simple spray that will cool a hot surface using FLUENT.

I am trying to do a spray simulation for the first time with Fluent. Features Of ANSYS Fluent. Spray modeling with Fluent.

Modeling amp simulation of rocket nozzle ijaegt. The VOF -DPM spray model is a new hybrid multi-phase model in FLUENT that will simulate spray processes with the finest details. 3- You will need to run an unsteady spray simulation where you have to look up the spray time duration in the experiment.

Retain the default value of 5 for Step Length Factor. Fluent VOF to DPM CFD Spray Model Examples This new model has gone through rigorous testing and several cases have been run successfully to completion. ANSYS Fluent Widest array of modeling capabilities Accurate capabilities to simulate a wide range of phenomena.

The model involves linear stability analysis which assumes that a two-dimensional viscous incompressible liquid sheet of thick-ness 2h moving with a relative velocity U through an inviscid. CFD Helps To Predict The Flow Behavior Of Spray Nozzle. Features of ansys fluent.

Ansys fluent 12 0 theory guide 15 9 1 the plain orifice. Can we use dense discrete phase model for air water spray in ansys fluent. Enable Droplet Collision and Droplet Breakup in the Spray Model group box.

This video tutorial demonstrates step by step procedure for spray simulation by using a discrete phase model DPM in ANSYS-Fluent. Tutorial 17 Modeling Evaporating Liquid Spray. Ansys Fluent can simulate swirling spray flames near extinction in a Cambridge bluff-body swirling burner.

Spray Modeling Tutorial Using Ansys i. Spray Modeling in Fluent 1. ANSYS-CFX Spary Modelling - Computational Fluid Dynamics.

ANSYS FLUENT 12 0 Theory Guide 15 9 1 The Plain Orifice. Read Book Spray Modeling Tutorial Using Ansys CfxNook Books Below are some of our favorite websites where you can download free ebooks that will work with just about any device or ebook reading app. Engine Model The engine under consideration is a Ruggerini RD 270 engine with the specifications shown in Table 1 Ruggerini 2003.

2- You will need to find the surface tension parameter for the sprayed fluid. I have applied all the DPM setting and defined injection parameters. The best practice documents and tutorials are also available upon request from Ansys Support on the Ansys Customer Portal.

Ansys Fluent Tutorial Spray Simulation By Using Dpm Model Youtube

Ansys Fluent Tutorial Spray Simulation By Using Dpm Model Youtube

Spray Dryer Ansys Fluent Cfd Simulation Training By Ansys Fluent Mr Cfd

Ansys Fluent Efficient Modeling Of Spray Breakup Using Vof To Dpm Transition Youtube

16 4 8 Creating A Spray Injection

Ansys Fluent Training Spray Cfd Simulation Using Injection In Dpm Youtube

Ansys Fluent 12 0 Tutorial Guide Step 7 Create A Spray Injection

0 comments

Post a Comment